I. kufupikitsa

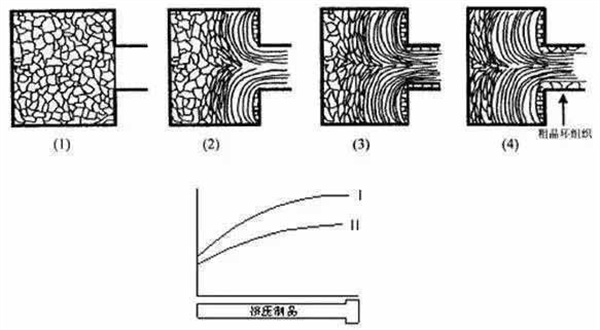

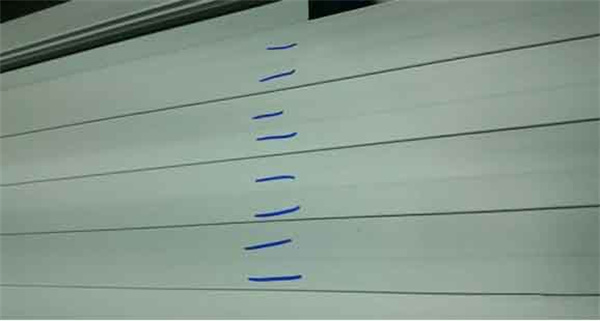

Pamapeto a mchira wa zinthu zina zowonjezera, pambuyo poyang'anitsitsa kukulitsa, pali chodabwitsa chofanana ndi nyanga pakati pa gawo la mtanda, lomwe limatchedwa kuchepa kwa mchira.

Kawirikawiri, mchira wa mankhwala opangira kutsogolo ndi wautali kuposa wa reverse extrusion, ndipo alloy yofewa ndi yaitali kuposa alloy hard.Kuchepa kwa chinthu chotuluka kutsogolo kumakhala ngati mawonekedwe a annular disjoint wosanjikiza, ndipo kuchepera kwa chinthu chobwerera kumbuyo kumakhala mawonekedwe apakati.

Chitsulocho chimatulutsidwa kumapeto kumbuyo, ndi khungu la ingot ndi zophatikizira zakunja zimasonkhanitsidwa pakona yakufa ya silinda ya extrusion kapena gasket ikuyenda mu mankhwala kuti apange shrinkage yachiwiri;pamene zinthu zotsalira ndi lalifupi kwambiri ndi pakati pa mankhwala insufficiently kudyetsedwa, mawonekedwe a mtundu wa chidule.Kuchokera kumapeto kwa mchira kupita kutsogolo, mchirawo pang'onopang'ono umakhala wopepuka ndikutha kwathunthu.

Chifukwa chachikulu cha kuchepa

1. Zinthu zotsalira ndizofupikitsa kwambiri kapena kutalika kwa mapeto odulidwawo sikukugwirizana ndi malamulo;

2. Pad extrusion si yoyera ndipo imakhala ndi madontho amafuta;

3. Pamapeto pake a extrusion, kuthamanga kwa extrusion kumathamanga kwambiri kapena kumawonjezeka mwadzidzidzi;

4. Gwiritsani ntchito chofinyira chopunduka (padiyo yokwezeka pakati);

5. Kutentha kwa silinda ya extrusion ndikokwera kwambiri;

6. Silinda ya extrusion ndi shaft extrusion sizigwirizana;

7. Pamwamba pa ingot si woyera, pali madontho a mafuta, zotupa za tsankho ndi kupukutira ndi zolakwika zina sizimachotsedwa;

8. Chingwe chamkati cha cylinder extrusion sichiri choyera kapena chopunduka, ndipo chingwe chamkati sichimatsukidwa ndi kuyeretsa nthawi.

Njira yopewera

1. Siyani zotsalira ndikudula michira ngati pakufunika;

2. Sungani nkhungu zoyera;

3. Kupititsa patsogolo khalidwe lapamwamba la ingot;

4. Moyenera kulamulira extrusion kutentha ndi liwiro kuonetsetsa yosalala extrusion;

5. Kupatula pazochitika zapadera, ndizoletsedwa kugwiritsa ntchito mafuta pamwamba pa chida ndi nkhungu;

6. The gasket bwino utakhazikika.

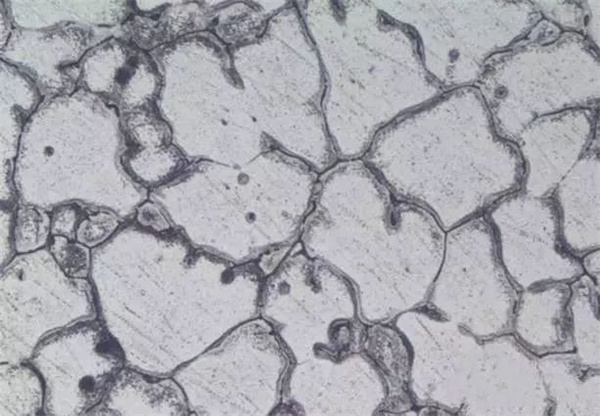

II.Mphete ya kristalo yowoneka bwino

Zinthu zina za aluminiyamu zomwe zidatulutsidwa zimapanga malo owoneka bwino atirigu m'mphepete mwa chinthucho pamayeso ocheperako pambuyo pa chithandizo chamankhwala, chomwe chimatchedwa mphete yambewu yolimba.Chifukwa cha mawonekedwe osiyanasiyana ndi njira zopangira mankhwala, mawonekedwe a mphete, arc-mawonekedwe a arc ndi mitundu ina ya mphete za coarse-grained zingapangidwe.Kuzama kwa mphete ya coarse-grained kumachepa pang'onopang'ono kuchokera kumchira kupita kutsogolo ndikutha kwathunthu.Njira yopangira mapangidwe ndi gawo laling'ono lambewu lomwe limapangidwa pamwamba pa chinthucho pambuyo pa kutulutsa kotentha, ndipo dera lambewu la coarse recrystallized chimapangidwa pambuyo pa kutentha ndi chithandizo chamankhwala.

Chifukwa chachikulu cha mphete ya kristalo

1. Osafanana extrusion mapindikidwe

2. Kutentha kwa kutentha kwa kutentha ndipamwamba kwambiri ndipo nthawi yogwira ndi yaitali kwambiri, kotero kuti mbewu zimakula;

3. Kapangidwe kakemidwe ka golidi kameneko ndi kopanda nzeru;

4. Ma alloys owonjezera omwe amatha kutentha kutentha amakhala ndi mphete zowonongeka pambuyo pa chithandizo cha kutentha, makamaka mawonekedwe ndi mipiringidzo ya 6a02, 2a50 ndi ma alloys ena ndi ovuta kwambiri, omwe sangathe kuthetsedwa ndipo amatha kulamulidwa mkati mwamtundu wina;

5. The extrusion deformation ndi yaying'ono kapena kusinthika sikukwanira, kapena mumtundu wovuta kwambiri, ndipo n'zosavuta kupanga mphete ya kristalo yolimba.

Njira yopewera

1. Khoma lamkati la cylinder extrusion ndi losalala komanso loyera, limapanga manja a aluminiyamu athunthu kuti achepetse kukangana panthawi ya extrusion;

2. The deformation iyenera kukhala yodzaza ndi yofanana momwe zingathere, ndipo magawo a ndondomeko monga kutentha ndi liwiro ayenera kuyendetsedwa bwino;

3. Pewani njira yothetsera kutentha kwapamwamba kwambiri kapena nthawi yayitali kwambiri;

4. Kutulutsa ndi porous kufa;

5. Extrusion by reverse extrusion njira ndi static extrusion njira;

6. Amapangidwa ndi njira yothetsera chithandizo-chojambula-kukalamba;

7. Sinthani kuchuluka kwa golide ndikuwonjezera chinthu choletsa recrystallization;

8. Gwiritsani ntchito kutentha kwapamwamba;

9. Ingots zina za alloy sizinapangike, ndipo mphete yambewu yomata imakhala yosazama panthawi yotulutsa.

III, wosanjikiza

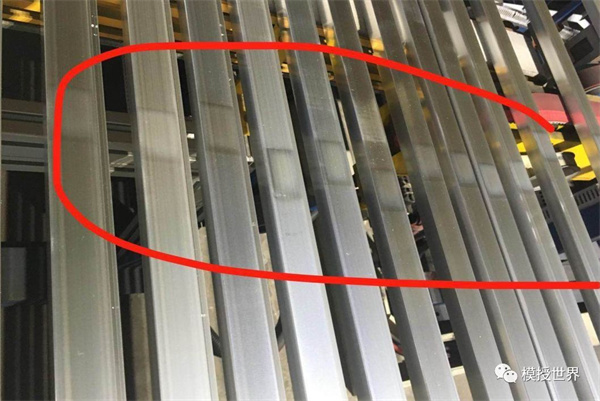

Ichi ndi khungu delamination chilema chopangidwa pamene zitsulo otaya ndi yunifolomu, ndi pamwamba ingot umayenda mu mankhwala pamodzi ndi mawonekedwe pakati nkhungu ndi kutsogolo mapeto zone zone.Pachiyeso chocheperako chocheperako, zikuwoneka kuti pali cholakwika cha zigawo zosiyanasiyana m'mphepete mwa gawolo.

Chifukwa chachikulu cha stratification

1. Pamwamba pa ingot pali fumbi kapena ingot ili ndi magulu akuluakulu a tsankho m'malo mwa khungu la galimoto, zotupa zachitsulo, ndi zina zotero, zomwe zimakhala zosavuta kupanga zigawo;

2. Pali ma burrs pamwamba pa chopanda kanthu kapena dothi monga madontho a mafuta, utuchi, etc., omwe samatsukidwa asanatulutsidwe;

3. Malo a dzenje lakufa ndi osamveka, pafupi ndi m'mphepete mwa silinda ya extrusion;

4. Chida cha extrusion chimavalidwa kwambiri kapena pali dothi mu tchire la silinda ya extrusion, yomwe singathe kutsukidwa ndikusinthidwa munthawi yake;

5. Kusiyana kwake kwa pad extrusion ndikokulirapo;

6. Kutentha kwa silinda ya extrusion ndipamwamba kwambiri kuposa ya ingot.

Njira yopewera

1. Kukonzekera koyenera kwa nkhungu, kuyang'ana panthawi yake ndikusintha zida zosayenerera;

2. Ingots zosayenerera sizimayikidwa mu ng'anjo;

3. Pambuyo podula zinthu zotsalira, ziyenera kutsukidwa popanda kumamatira ku mafuta odzola;

4. Sungani mzere wa silinda ya extrusion, kapena yeretsani nthawi yake ndi gasket.

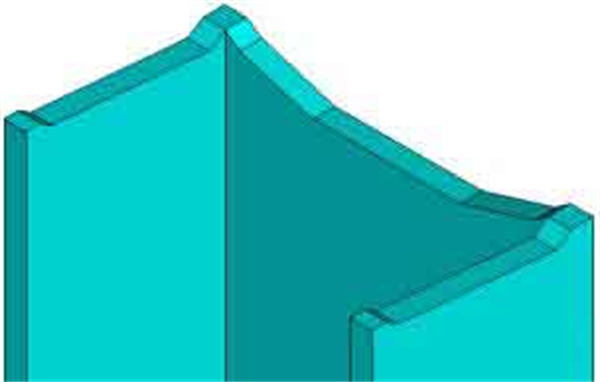

IV.Kuwotcherera kosakwanira

Chodabwitsa cha kuwotcherera delamination kapena chosakwanira kuwotcherera za dzenje mankhwala extruded ndi kugawanika kufa pa weld amatchedwa osauka kuwotcherera.

Chifukwa chachikulu cha osauka kuwotcherera

1. The extrusion coefficient ndi yaying'ono, kutentha kwa extrusion kumakhala kochepa, ndipo kuthamanga kwa extrusion kuli mofulumira;

2. Ubweya wotulutsa kapena zida sizoyera;

3. Mafuta nkhungu;

4. Kukonzekera kwa nkhungu kosayenera, kusakwanira kapena kusagwirizana kwa hydrostatic pressure, mapangidwe osayenera a mabowo a shunt;

5. Pamwamba pa ingot pali banga la mafuta.

Njira yopewera

1. Moyenera kuonjezera extrusion coefficient, extrusion kutentha ndi extrusion liwiro;

2. Kupanga koyenera ndi kupanga nkhungu;

3. The extrusion yamphamvu ndi extrusion gasket si opaka mafuta ndi kukhala woyera;

4. Gwiritsani ntchito ma ingots okhala ndi malo oyera.

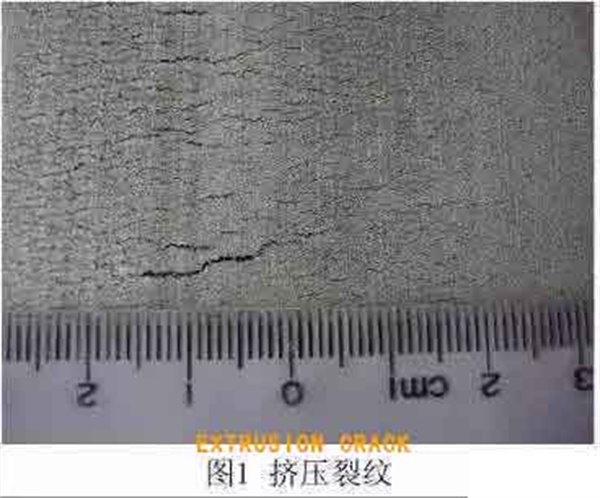

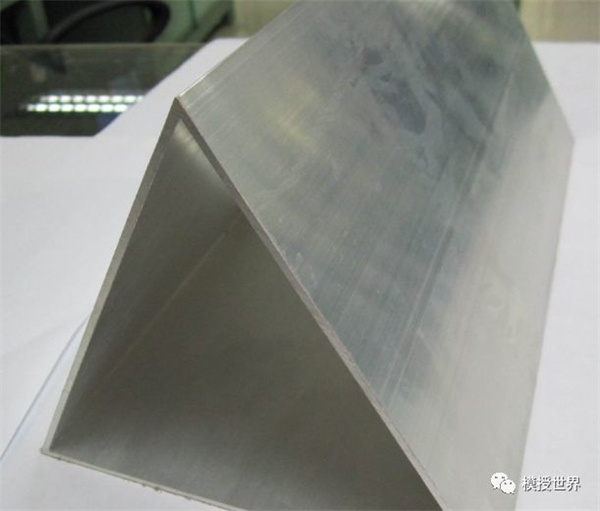

V. Extrusion ming'alu

Uwu ndi mng'alu wowoneka ngati arc m'mphepete mwa gawo loyeserera la chinthu chomwe chatulutsidwa, komanso kusweka kwapang'onopang'ono pang'onopang'ono motsatira njira yake yotalikirapo, yomwe imabisika pansi pa epidermis mumilandu yopepuka, ndi ming'alu yakunja. pazovuta kwambiri, zomwe zingawononge kwambiri kupitiriza kwachitsulo.Ming'alu ya Extrusion imapangidwa pamene chitsulo chimang'ambika ndi kupsinjika kwanthawi ndi nthawi kwa khoma lakufa panthawi ya extrusion.

Chifukwa chachikulu cha extrusion ming'alu

1. Kuthamanga kwa extrusion ndikothamanga kwambiri;

2. Kutentha kwa Extrusion ndikokwera kwambiri;

3. Kuthamanga kwa extrusion kumasinthasintha kwambiri;

4. Kutentha kwa ubweya wotuluka ndi wokwera kwambiri;

5. Pamene kufa kwa porous kumatulutsidwa, makonzedwe a kufa amakhala pafupi kwambiri ndi pakati, kotero kuti zitsulo zapakati sizikwanira, kotero kuti kusiyana pakati pa pakati ndi kuthamanga kwa m'mphepete kumakhala kwakukulu;

6. The ingot homogenization annealing si zabwino.

Njira yopewera

1. M'pofunika kukhazikitsa zosiyanasiyana Kutentha ndi extrusion specifications;

2. Kuwunika pafupipafupi zida ndi zida kuti zitsimikizire kuti zimagwira ntchito bwino;

3. Sinthani kapangidwe ka nkhungu ndikuyikonza mosamala, makamaka mapangidwe a mlatho wa nkhungu, chipinda chowotcherera ndi utali wozungulira, etc. ziyenera kukhala zololera;

4. Chepetsani kuchuluka kwa sodium muzitsulo zapamwamba za magnesium aluminium;

5. Ingot ndi homogenized ndi annealed kuti pulasitiki yake ndi yunifolomu.

VI.Mibulu

Chitsulo chapakhungu cham'deralo chimasiyanitsidwa mosalekeza kapena mosalekeza ndi chitsulo choyambira, ndipo chimawoneka ngati chozungulira chozungulira kapena choboola pakati, chomwe chimatchedwa bubble.

Chifukwa chachikulu cha thovu

1. Pamene extruding, silinda extrusion ndi extrusion pad ndi dothi monga chinyezi ndi mafuta;

2. Chifukwa cha kuvala kwa silinda ya extrusion, mpweya pakati pa gawo lowonongeka ndi ingot umalowa muzitsulo panthawi ya extrusion;

3. M'mafuta muli chinyezi;

4. Dongosolo la ingot palokha lili ndi zolakwika zotayirira komanso za porosity;

5. Kutentha kwa kutentha kwa kutentha ndikwambiri, nthawi yogwira ndi yotalika kwambiri, ndipo chinyezi chamlengalenga mu ng'anjo ndichokwera;

6. Mafuta a haidrojeni omwe ali muzinthuzo ndi okwera kwambiri;

7. Kutentha kwa silinda ya Extrusion ndi kutentha kwa ingot ndizokwera kwambiri.

Njira yopewera

1. Pamwamba pa zida ndi ingots ziyenera kukhala zoyera, zosalala ndi zowuma;

2. Kupanga moyenerera kukula kofananira kwa silinda ya extrusion ndi gasket extrusion, yang'anani kukula kwa chida nthawi zambiri, kukonzanso silinda ya extrusion mu nthawi yomwe pali mimba yayikulu, ndipo gasket yotulutsa sayenera kukhala yololera;

3. Onetsetsani kuti mafutawo ndi aukhondo komanso owuma;

4. Kutsatira mosamalitsa ndondomeko ya ntchito ya extrusion, kutulutsa nthawi, kudula bwino, osagwiritsa ntchito mafuta, kuchotsani zinthu zotsalira, kusunga zotsalira ndi nkhungu zoyera komanso zosadetsedwa.

VII.Peeling

Ichi ndi chodabwitsa cha kulekanitsa kwanuko pakati pa chitsulo chapakhungu ndi chitsulo choyambira cha aluminium alloy extrusion product.

Chifukwa chachikulu cha peeling

1. Pamene alloy yasinthidwa ndikutulutsidwa, khoma lamkati la silinda ya extrusion limatsatiridwa ndi chitsamba chopangidwa ndi chitsulo choyambirira, chomwe sichimatsukidwa bwino;

2. Silinda ya extrusion ndi pad extrusion sizikugwirizana bwino, ndipo khoma lamkati la silinda ya extrusion limakhala ndi zitsulo zotsalira zam'deralo;

3. Iwo extruded ndi lubricating extrusion yamphamvu;

4. Pali chitsulo pa dzenje lakufa kapena lamba wogwira ntchito wakufayo ndi wautali kwambiri.

Njira yopewera

1. Tsukani bwinobwino silinda ya extrusion pamene mukutulutsa alloy;

2. Pangani moyenerera kukula kofananira kwa silinda ya extrusion ndi gasket extrusion, fufuzani kukula kwa chida pafupipafupi, ndipo gasket yotulutsa sichitha kulekerera;

3. Tsukani zitsulo zotsalira pa nkhungu mu nthawi.

VIII.Zokanda

Zipsera zamakina zokhala ndi mizere imodzi zomwe zimayambitsidwa ndi kukhudzana pakati pa zinthu zakuthwa ndi pamwamba pa chinthucho panthawi yotsetsereka yachibale zimatchedwa scratches.

Chifukwa chachikulu cha mikanda

1. Kusonkhanitsa kosayenera kwa zida, maupangiri osawoneka bwino ndi ma worktables, ngodya zakuthwa kapena zinthu zakunja, ndi zina zotero;

2. Pali tchipisi tachitsulo pa lamba wogwira ntchito nkhungu kapena lamba wogwirira ntchito wawonongeka;

3. Muli mchenga kapena zitsulo zosweka m'mafuta opaka mafuta;

4. Kugwira ntchito molakwika panthawi yoyendetsa ndi kufalitsa kosayenera.

Njira yopewera

1. Yang'anani ndi kupukuta lamba wogwirira ntchito mu nthawi yake;

2. Yang'anani njira yotuluka ya mankhwala, iyenera kukhala yosalala, ndipo njira yowongoka ingathe kudzozedwa bwino;

3. Pewani kusisita ndi kukanda pamakina pogwira.

IX.Mabampu

Zipsera zomwe zimapangika pamwamba pa zinthuzo kapena zomwe zidagundana ndi zinthu zina zimatchedwa kuvulala koopsa.

Chifukwa chachikulu cha tokhala

1. Kapangidwe ka workbench ndi rack chuma n'zosamveka;

2. Kutetezedwa kwachitsulo kosayenera kwa madengu azinthu, zoyikapo zakuthupi, ndi zina zotero;

3. Musayigwire mosamala mukamagwira ntchito.

Njira yopewera

1. Kugwira ntchito mosamala, gwirani mosamala;

2. Pewani ngodya zakuthwa, ndikuphimba dengu ndi rack ndi dunnage ndi zipangizo zofewa.

X. Zikanda

The zipsera anagawira mitolo pamwamba pa mankhwala chifukwa cha kutsetsereka wachibale kapena dislocation pambuyo pamwamba mankhwala extruded akumana ndi m'mbali kapena pamwamba zinthu zina amatchedwa zokopa.

Chifukwa chachikulu cha mikanda

1. Chikombolecho chavala kwambiri;

2. Chifukwa cha kutentha kwakukulu kwa ingot, dzenje lakufa limamatira ku aluminiyamu kapena lamba wogwirira ntchito wakufa wawonongeka;

3. Dothi monga graphite ndi mafuta amagwera mu cylinder extrusion;

4. Zogulitsazo zimasuntha wina ndi mzake, kotero kuti pamwamba pake amawombera ndipo kutuluka kwa extrusion kumakhala kosagwirizana, zomwe zimapangitsa kuti mankhwalawo asayendetsedwe molunjika, zomwe zimapangitsa kuti pakhale zokopa pakati pa zinthu ndi njira yowongoka komanso yogwiritsira ntchito.

Njira yopewera

1. Yang'anani ndikusintha nkhungu zosayenerera pakapita nthawi;

2. Onetsetsani kutentha kwa ubweya wa ubweya;

3. Onetsetsani kuti pamwamba pa cylinder extrusion ndi ubweya wa ubweya ndi woyera ndi wouma;

4. Control liwiro extrusion kuonetsetsa liwiro yunifolomu.

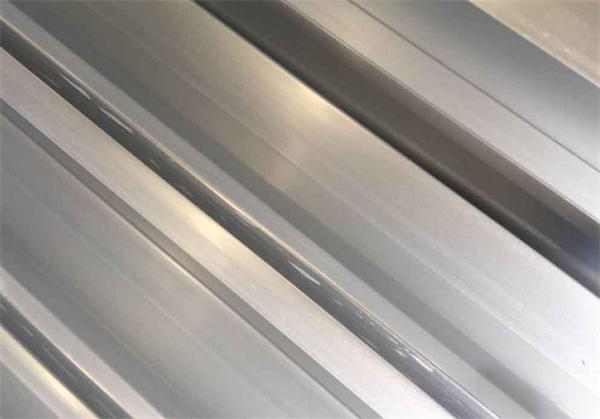

XI.Zizindikiro za nkhungu

Ichi ndi chiwopsezo cha kusagwirizana kwautali pamtunda wa chinthu chotuluka, ndipo zinthu zonse zotulutsidwa zili ndi zizindikiro zofa mosiyanasiyana.

Chifukwa chachikulu cha zizindikiro nkhungu

Chifukwa chachikulu: lamba wogwira ntchito wa nkhungu sangathe kukwaniritsa kusalala kwathunthu.

Njira yopewera

1. Onetsetsani kuti pamwamba pa lamba wogwira ntchito nkhungu ndi woyera, wosalala komanso wopanda nsonga zakuthwa;

2. Wololera nitriding mankhwala kuonetsetsa mkulu pamwamba kuuma;

3. Konzani bwino nkhungu;

4. Lamba wogwira ntchito ayenera kupangidwa momveka bwino, ndipo lamba wogwira ntchito sayenera kukhala wamtali kwambiri.

XII.Pindani, pindani, gwedezani

Chodabwitsa chomwe gawo la mtanda la mankhwala opangidwa ndi extruded limapotozedwa mozungulira mozungulira limatchedwa kupotoza.Chodabwitsa kuti mankhwalawo amapindika kumbali yautali kapena mawonekedwe a mpeni samawongoka amatchedwa kupindika.The mosalekeza undulating chodabwitsa chimene chimapezeka mu malangizo longitudinal mankhwala amatchedwa yoweyula.

Zomwe zimayambitsa kupindika, kupindika, ndi mafunde

1. Mapangidwe ndi makonzedwe a mabowo amafa sali abwino, kapena kugawidwa kwa kukula kwa lamba wogwira ntchito sikumveka;

2. Osauka Machining olondola mabowo kufa;

3. Kalozera woyenera sanayikidwe;

4. Kukonza nkhungu molakwika;

5. Zolakwika extrusion kutentha ndi liwiro;

6. Mankhwalawa samawongoleredwa musanalandire chithandizo;

7. Kuzizira kosagwirizana panthawi ya chithandizo cha kutentha kwa intaneti.

Njira yopewera

1. Mulingo wapamwamba wa mapangidwe a nkhungu ndi kupanga;

2. Ikani kalozera woyenera, kukokera ndi kutulutsa;

3. Gwiritsani ntchito mafuta am'deralo, kukonza nkhungu ndi kusokoneza kapena kusintha mapangidwe a dzenje la shunt kuti musinthe kayendedwe kachitsulo;

4. Moyenera kusintha extrusion kutentha ndi liwiro kuti mapindikidwe yunifolomu;

5. Moyenera kuchepetsa kutentha kwa njira yothetsera kutentha kapena kuonjezera kutentha kwa madzi kuti muthetse mankhwala;

6. Onetsetsani kuti yunifolomu kuzirala pa Intaneti quenching.

XIII.Kupinda kolimba

Kupindika kwadzidzidzi kwa chinthu chotuluka kwinakwake m'mbali mwake kumatchedwa kupindika kolimba.

Chifukwa chachikulu cha kupinda mwamphamvu

1. Liwiro losagwirizana la extrusion, kusintha kwadzidzidzi kuchokera ku liwiro lotsika kupita ku liwilo lalikulu, kapena kusintha kwadzidzidzi kuchokera ku liwilo kupita ku liwiro lotsika, ndikuyimitsa mwadzidzidzi;

2. Mosasunthika kusuntha mankhwala pa ndondomeko extrusion;

3. Malo ogwirira ntchito a extruder ndi osagwirizana.

Njira yopewera

1. Osayima mwachisawawa kapena kusintha liwiro la extrusion mwadzidzidzi;

2. Osasuntha mbiriyo mwadzidzidzi ndi dzanja;

3. Onetsetsani kuti tebulo lotulutsa liri lathyathyathya ndipo tebulo la kutulutsa liri losalala, lopanda zinthu zachilendo, ndipo chophatikizika chophatikizika sichimasokoneza.

XIV.Zakudya za hemp

Izi ndi pamwamba chilema cha extruded mankhwala, kutanthauza kuti pamwamba pa mankhwala ndi mosalekeza flakes, malo zokopa, maenje, zitsulo nyemba, etc. ndi yaing'ono unevenness.

Chifukwa chachikulu cha pockmark

1. Kuuma kwa nkhungu sikukwanira kapena kuuma kwake sikufanana;

2. Kutentha kwa Extrusion ndikokwera kwambiri;

3. The extrusion liwiro kwambiri;

4. Lamba wogwirira ntchito wa nkhungu ndi wautali kwambiri, wovuta kapena womangidwa ndi chitsulo;

5. Ubweya wotuluka ndi wautali kwambiri.

Njira yopewera

1. Kupititsa patsogolo kuuma ndi kuuma kufanana kwa lamba wogwirira ntchito nkhungu;

2. Kutenthetsa cylinder extrusion ndi ingot malinga ndi malamulo, ndikugwiritsa ntchito liwiro loyenera la extrusion;

3. Kupanga nkhungu moyenerera, kuchepetsa kuuma kwa lamba wogwirira ntchito, ndikulimbikitsa kuyang'ana pamwamba, kukonza ndi kupukuta;

4. Gwiritsani ntchito utali wokwanira wa ingot.

XV.Kukanikiza zitsulo

Panthawi ya extrusion, tchipisi tachitsulo timapanikizidwa pamwamba pa chinthucho, chomwe chimatchedwa kukanikiza kwachitsulo.

Zifukwa zazikulu za kulowerera kwachitsulo:

1. Nthambi zaubweya ndizolakwika;

2. Mkati mwa ubweya wa ubweya umakanizidwa ndi zitsulo kapena mafuta opaka mafuta ali ndi zinyalala zachitsulo ndi dothi lina;

3. Silinda ya extrusion simatsukidwa, ndipo pali zinyalala zina zachitsulo;

4. Ingot imamira muzitsulo zina zakunja;

5. Pali kuphatikizidwa kwa slag mu ubweya.

Njira yopewera

1. Chotsani ziboliboli pa ubweya;

2. Onetsetsani kuti pamwamba pa ubweya ndi mafuta opaka mafuta ndi oyera ndi owuma;

3. Tsukani zinyalala zachitsulo mu nkhungu ndi extrusion cylinder;

4. Sankhani ubweya wapamwamba kwambiri.

XVI.Kukanikiza kopanda chitsulo

Zinthu zakunja monga mwala wakuda zimakanikizidwa mkati ndi kunja kwa chinthu chotuluka, chomwe chimatchedwa non-metal indentation.Zinthu zakunja zitachotsedwa, mkati mwa chinthucho chidzawonetsa kupsinjika kwamitundu yosiyanasiyana, zomwe zidzawononge kupitiliza kwa zinthuzo.

Chifukwa chachikulu cha kulowetsedwa kwazitsulo zopanda zitsulo

1. The graphite tinthu kukula ndi coarse kapena agglomerated, munali chinyezi kapena mafuta, ndi yoyambitsa ndi wosagwirizana;

2. Kung'anima kwa mafuta a silinda ndi otsika;

3. Chiŵerengero cha mafuta a silinda ndi graphite ndi chosayenera, ndipo pali graphite yambiri.

Njira yopewera

1. Gwiritsani ntchito graphite yoyenerera ndikuyimitsa;

2. Sefa ndi kugwiritsa ntchito mafuta odzola oyenerera;

3. Kuwongolera chiŵerengero cha mafuta opaka mafuta ndi graphite.

XVII.Pamwamba dzimbiri

Zogulitsa zowonjezera zomwe sizinachitikepo chithandizo chapamwamba, pamwamba pa mankhwala opangidwa ndi extruded, pambuyo pa mankhwala kapena electrochemical reaction ndi kunja sing'anga, zimayambitsa chilema chifukwa cha kuwonongeka kwa m'deralo, komwe kumatchedwa pamwamba corrosion.Pamwamba pa zinthu zowonongeka zimataya kuwala kwake kwachitsulo, ndipo zikavuta kwambiri, zinthu zowonongeka zoyera zimapangidwira pamwamba.

Chifukwa chachikulu cha dzimbiri pamwamba

1. Mankhwalawa amawonekera kuzinthu zowonongeka monga madzi, asidi, alkali, mchere, etc. panthawi yopanga, kusungirako ndi kunyamula katundu, kapena kuyimitsidwa mumlengalenga kwa nthawi yaitali;

2. Zolakwika aloyi zikuchokera chiŵerengero;

Njira yopewera

1. Sungani mankhwala pamwamba ndi kupanga ndi kusungirako malo aukhondo ndi owuma;

2. Kuwongolera zomwe zili mu aloyi.

XVIII.Peel ya Orange

Pamwamba pa mankhwala opangidwa ndi extruded amakhala ndi makwinya osagwirizana ngati peel lalanje, yomwe imatchedwanso makwinya.Zimayambitsidwa ndi njere zazikuluzikulu panthawi ya extrusion.Mbewu zikachuluka, m'pamenenso makwinya amaonekera.

Chifukwa chachikulu cha peel lalanje

1. Mapangidwe a ingot ndi osagwirizana ndipo chithandizo cha homogenization sichikwanira;

2. Zomwe zimatuluka ndizosamveka, ndipo njere za zinthu zomalizidwa ndizovuta;

3. Kuchuluka kwa kutambasula ndi kuwongola ndi kwakukulu kwambiri.

Njira yopewera

1. Moyenera kulamulira ndondomeko homogenization;

2. Mapindikidwe ayenera kukhala ofanana momwe angathere (kuwongolera kutentha kwa extrusion, liwiro, etc.)

3. Sinthani kuchuluka kwa kuwongolera kwamphamvu kuti kusakhale kwakukulu.

XIX.Zosafanana

Pambuyo pa extrusion, malo omwe makulidwe a mankhwalawa amasintha pa ndege amawoneka ngati concave kapena convex.Nthawi zambiri, sizingawonekere ndi maso.Pambuyo pa chithandizo chapamwamba, mithunzi yabwino kapena mithunzi ya mafupa imawonekera.

Chifukwa chachikulu cha kusamvana

1. Lamba wogwirira ntchito wa nkhungu sanapangidwe bwino, ndipo kukonza nkhungu sikuli m'malo;

2. Kukula kwa dzenje la shunt kapena pre-chamber sikoyenera, ndipo mphamvu yokoka kapena kukulitsa mbiri mu gawo la mtanda imayambitsa kusintha pang'ono mu ndege;

3. Njira yoziziritsa imakhala yosagwirizana, ndipo liwiro lozizira la gawo lakuda-lalitali kapena gawo lodutsana limakhala pang'onopang'ono, zomwe zimapangitsa kuti pakhale kusiyana kosiyana ndi kusinthika kwa ndege panthawi yozizira;

4. Chifukwa cha kusiyana kwakukulu kwa makulidwe, kusiyana pakati pa gawo lolimba-mipanda kapena bungwe la kusintha kwa malo ndi mbali zina za bungwe kumawonjezeka.

Njira yopewera

1. Kupititsa patsogolo mlingo wa mapangidwe a nkhungu, kupanga ndi kukonza nkhungu;

2. Onetsetsani kuti yunifolomu kuzirala liwiro.

XX.Chitsanzo cha kugwedera

Ichi ndi cholakwika chanthawi ndi nthawi chodutsa pamwamba pa chinthu chotuluka.Amadziwika ndi mikwingwirima yopingasa mosalekeza pamtunda wa chinthucho, ndipo mizere yokhotakhota imagwirizana ndi mawonekedwe a lamba wogwirira ntchito wa nkhungu, ndipo muzovuta kwambiri, pamakhala kumverera kowoneka bwino.

Chifukwa chachikulu cha kugwedezeka

1. Mtsinje wa extrusion umapita patsogolo ndikugwedezeka chifukwa cha zifukwa za zipangizo, zomwe zimapangitsa kuti chitsulo chigwedezeke pamene chikutuluka mu dzenje;

2. Chitsulo chimagwedezeka chikatuluka mu dzenje lakufa chifukwa cha nkhungu;

3. Pulogalamu yothandizira nkhungu si yoyenera, kukhazikika kwa nkhungu sikwabwino, ndipo kugwedezeka kumachitika pamene mphamvu ya extrusion imasintha.

Njira yopewera

1. Gwiritsani ntchito nkhungu zoyenerera;

2. Zothandizira zoyenerera ziyenera kugwiritsidwa ntchito pamene nkhungu imayikidwa;

3. Sinthani zida.

XXI, Zosakaniza

Chifukwa chachikulu cha inclusions

Popeza kuphatikizika kwa billet kumakhala ndi zitsulo kapena zopanda zitsulo, sikunapezeke mu ndondomeko yapitayi, ndipo kumakhalabe pamtunda kapena mkati mwa mankhwala pambuyo pa extrusion.

Njira yopewera

Limbikitsani kuyendera kwa billet (kuphatikiza kuyang'ana kwa akupanga) kuti muteteze billet yomwe ili ndi zitsulo kapena zosagwirizana ndi zitsulo kuti isalowe munjira ya extrusion.

XXII, Zizindikiro zamadzi

Zoyera zoyera kapena zakuda zowoneka bwino zamadzi zomwe zili pamwamba pa mankhwalawa zimatchedwa madzi.

Chifukwa chachikulu cha zizindikiro za madzi

1. Kuyanika sikuli bwino pambuyo poyeretsa, ndipo pali chinyezi chotsalira pamwamba pa mankhwala;

2. Chinyezi chotsalira pamwamba pa mankhwala chifukwa cha mvula ndi zifukwa zina sizinayeretsedwe mu nthawi;

3. Mafuta a ng'anjo yokalamba amakhala ndi madzi, ndipo madzi amasungunuka pamwamba pa mankhwala panthawi ya kuzizira kwa mankhwala pambuyo pa ukalamba;

4. Mafuta a ng'anjo yokalamba sakhala oyera, ndipo pamwamba pa mankhwalawo amawonongeka ndi sulfure dioxide pambuyo pa kuyaka kapena kuipitsidwa ndi fumbi;

5. Chozimitsira moto chaipitsidwa.

Njira yopewera

1. Sungani pamwamba pa chinthucho chouma ndi choyera;

2. Kuwongolera chinyezi ndi ukhondo wa ukalamba;

3. Limbikitsani kasamalidwe ka quenching sing'anga.

XXIII.Mpata

Wolamulirayo ali pamwamba pa ndege ina ya mankhwala otulutsidwa, ndipo pali kusiyana pakati pa wolamulira ndi pamwamba, komwe kumatchedwa kusiyana.

Chifukwa chachikulu cha kusiyana

Kuthamanga kwachitsulo chosagwirizana panthawi ya extrusion kapena molakwika kumaliza ndi kuwongola ntchito.

Njira yopewera

Kupanga ndi kupanga nkhungu moyenera, kulimbitsa kukonza nkhungu, ndikuwongolera kutentha kwa extrusion ndi kuthamanga kwa extrusion motsatira malamulo.

XXIV, makulidwe a khoma losafanana

Extruded mankhwala ofanana kukula ndi woonda kapena wandiweyani makoma mu gawo lomwelo kapena longitudinal malangizo, ndipo chodabwitsa amatchedwa osagwirizana khoma makulidwe.

Chifukwa chachikulu cha m'lifupi khoma makulidwe

1. Mapangidwe a nkhungu ndi osamveka, kapena chida ndi msonkhano wa nkhungu ndi wosayenera;

2. The extrusion yamphamvu ndi extrusion singano si pa centerline yemweyo, kupanga eccentricity;

3. Chingwe cha silinda ya extrusion chimavala kwambiri, ndipo nkhunguyo siingathe kukhazikika, zomwe zimapangitsa kuti zikhale zosavuta;

4. Makulidwe a khoma lopanda kanthu la ingot lokhalokha sangathe kuthetsedwa pambuyo pa extrusions yoyamba ndi yachiwiri.Kuchuluka kwa khoma la ubweya wa ubweya pambuyo pa extrusion sikuchotsedwa pambuyo pogubuduza ndi kutambasula;

5. Mafuta odzola amagwiritsidwa ntchito mosagwirizana, zomwe zimapangitsa kuti zitsulo zisamayende bwino.

Njira yopewera

1. Konzani kamangidwe ndi kupanga zida ndi nkhungu, ndikusonkhanitsa mwanzeru ndikusintha;

2. Sinthani pakati pa extruder ndi extrusion kufa;

3. Sankhani osasoweka oyenerera;

4. Wololera kulamulira extrusion kutentha, extrusion liwiro ndi magawo ena ndondomeko.

XXV.Onjezani (ndi) pakamwa

Chilema chomwe mbali ziwiri za zinthu zomwe zatulutsidwa monga groove ndi mawonekedwe a I zimatsatiridwa kunja zimatchedwa flaring, ndipo chilema chomwe chimalowera mkati chimatchedwa kutsegulira kofanana.

Zomwe zimayambitsa kukula (kuphatikiza)

1. Kuthamanga kwachitsulo kwa "miyendo" iwiri (kapena "mwendo" umodzi) wa ufa kapena mbiri yofananira kapena mbiri yofanana ndi I ndi yosagwirizana;

2. Kuthamanga kwa lamba wogwirira ntchito kumbali zonse za mbale ya pansi pa groove ndi yosiyana;

3. Makina owongoka osayenera;

4. Mankhwalawa akatuluka mu dzenje la nkhungu, chithandizo chamankhwala pa intaneti chimakhala chokhazikika mosagwirizana.

Njira yopewera

1. Kuwongolera kwambiri kuthamanga kwa extrusion ndi kutentha kwa extrusion;

2. Onetsetsani kuti kuzirala kuli kofanana;

3. Konzani bwino ndi kupanga nkhungu;

4. Kuwongolera kwambiri kutentha kwa extrusion ndi liwiro, ndikuyika chida ndikufa moyenera.

XXVI.Zizindikiro zowongoka

Mitsempha ya helical yomwe imapangidwa pamene mpukutu wapamwamba wa mankhwala opangidwa ndi extruded umawongoka umatchedwa zizindikiro zowongoka, ndipo zizindikiro zowongoka sizingapewedwe kwa chinthu chilichonse chowongoka ndi mpukutu wapamwamba.

Chifukwa chachikulu cha kuwongola zizindikiro

1. Pali m'mphepete pa chodzigudubuza pamwamba pa wodzigudubuza wowongoka;

2. Kupindika kwa mankhwala ndi kwakukulu kwambiri;

3. Kupanikizika kwambiri;

4. Ngodya ya wodzigudubuza ndi yaikulu kwambiri

5. Mankhwalawa ali ndi ovality yaikulu.

Njira yopewera

Chitani zinthu zoyenera kuti musinthe mogwirizana ndi zomwe zimayambitsa.

XXVII.Kuyimitsa zizindikiro, kuwonekera pompopompo, zizindikiro zoluma

Lekani extrusion pa extrusion kubala mikwingwirima padziko mankhwala ndi perpendicular kwa malangizo extrusion, otchedwa amasiya zizindikiro;mizere kapena mikwingwirima pamwamba pa chinthucho ndi perpendicular to extrusion direction during extrusion , zotchedwa zizindikiro zolumidwa kapena zowonekera pompopompo (zomwe zimadziwika kuti "zoimika magalimoto zabodza")

Pa extrusion, ZOWONJEZERA kuti stably kutsatira pamwamba lamba ntchito nthawi yomweyo detached ndi kutsatira pamwamba pa mankhwala extruded kupanga mapangidwe.Mikwingwirima yopingasa ya lamba wogwira ntchito yomwe imawoneka pamene extrusion imayimitsidwa imatchedwa zizindikiro zoimika magalimoto;mikwingwirima yomwe imawoneka panthawi ya extrusion imatchedwa kuwonetsa nthawi yomweyo kapena zizindikiro zoluma, ndipo imapanga phokoso panthawi ya extrusion.

Zomwe zimayambitsa kuyimitsidwa, zizindikiro pompopompo, ndi zizindikiro zoluma

1. Osafanana Kutentha kutentha kwa ingot kapena kusintha mwadzidzidzi extrusion liwiro ndi kuthamanga;

2. Zigawo zazikulu za nkhungu zimapangidwira bwino komanso zimapangidwira, kapena msonkhanowu ndi wosagwirizana ndipo pali mipata;

3. Pali kunja mphamvu perpendicular kwa malangizo extrusion;

4. Extruder sikuyenda bwino, ndipo pali chodabwitsa chokwawa.

Njira yopewera

1. Kutentha kwakukulu, kuthamanga kwapang'onopang'ono ndi yunifolomu extrusion, mphamvu ya extrusion imakhalabe yokhazikika;

2. Kuletsa mphamvu kunja mu ofukula extrusion malangizo kuchita pa mankhwala;

3. Kukonzekera koyenera kwa zida ndi nkhungu, kusankha kolondola kwa zipangizo za nkhungu, kufanana ndi kukula, mphamvu ndi kuuma.

XXVIII.Zotupa pakatikati

The zokopa pa pamwamba padziko la mankhwala extruded pa ndondomeko extrusion amatchedwa mkati padziko zokopa.

Chifukwa chachikulu cha mkati padziko abrasion

1. Singano yotuluka imamangidwa ndi chitsulo;

2. Kutentha kwa singano ya extrusion ndi yochepa;

3. Ubwino wa pamwamba wa singano extrusion ndi osauka ndipo pali tokhala;

4. Kutentha kwa extrusion ndi kuthamanga sikuyendetsedwa bwino;

5. Zolakwika chiŵerengero cha mafuta extrusion;

Njira yopewera

1. Kuonjezera kutentha kwa yamphamvu extrusion ndi extrusion singano, ndi kulamulira extrusion kutentha ndi extrusion liwiro;

2. Limbikitsani kusefera kwamafuta opaka mafuta, fufuzani kapena kusintha mafuta otayira pafupipafupi, ndikuthira mafuta mofanana ndi moyenera;

3. Pamwamba paubweya pazikhala paukhondo;

4. Bwezerani zisamere pachakudya zosayenerera ndi singano zotulutsira mu nthawi, ndipo sungani pamwamba pa nkhungu zowonongeka ndi zosalala.

XXX.Zinthu zina

Mwachidule, pambuyo pa chithandizo chokwanira, mitundu 30 ya zolakwika zomwe zatchulidwa pamwambapa zotayidwa aloyi extrusion zitha kuthetsedwa bwino, apamwamba, zokolola zambiri, moyo wautali, ndi kukongola kwazinthu, kupanga mtundu, kubweretsa nyonga ndi kulemera kwa bizinesi, ndi kukhala ndi phindu lalikulu laukadaulo ndi zachuma.

XXX.Zinthu zina

Mwachidule, pambuyo pa chithandizo chokwanira, mitundu 30 ya zolakwika zomwe zatchulidwa pamwambapa zotayidwa aloyi extrusion zitha kuthetsedwa bwino, apamwamba, zokolola zambiri, moyo wautali, ndi kukongola kwazinthu, kupanga mtundu, kubweretsa nyonga ndi kulemera kwa bizinesi, ndi kukhala ndi phindu lalikulu laukadaulo ndi zachuma.

Nthawi yotumiza: Aug-14-2022