Refractory Ceramic Distributing Launder for Aluminium billet casting

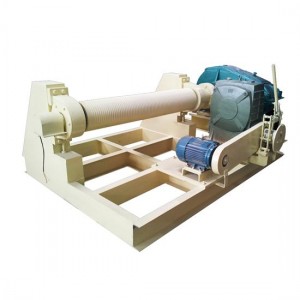

Makina ochapira amagwiritsidwa ntchito patebulo loponyera la makina oponyera, makamaka oyenera kuponya pamwamba pa aluminiyumu ndi aloyi ya aluminiyamu.

Makina ochapira amapangidwa kuchokera ku aluminiyamu silicate fiber ndi zida za ceramic composite.Ili ndi mawonekedwe amphamvu kwambiri;kukana etching aluminium amadzimadzi, kugwiritsidwa ntchito kwanthawi yayitali sikuli zinyalala, moyo wautali, komanso zotsatira zabwino zotchinjiriza.Ndilo chisankho chabwino kwambiri chopangira nsanja.

Distribution launder wamba kukula kwa billets ngati 3, 4, 5, 6, 7, 8, 9, 10, 12, 14, 16, 18 ", 20 ", komanso akhoza kupanga masaizi osiyanasiyana malinga ndi zofuna za makasitomala.

| Kachulukidwe Kg/m3 | 135-145 |

| Flexural mphamvu Mpa | >6 |

| SiO2 | 60% |

| Al2O3 | 15% |

| CaO | 15% |

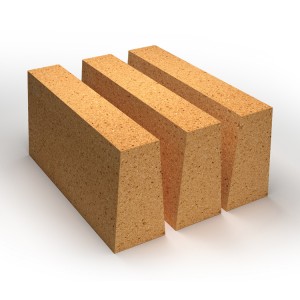

Zinthu zazikuluzikulu zamagawo osakanikirana a silika ceramic ndikuchita bwino kwa kutentha kwamafuta, kukana kutentha kwambiri, aluminiyamu yopanda ndodo, mphamvu yayikulu, yopanda delamination, komanso moyo wautali wautumiki.Zofunikira pakuchita zinthu:

Kutentha kwanthawi yayitali (℃): 1100

Gulu ntchito kutentha (℃): 1650

Thermal conductivity (W/mk): <1

Kuchulukana (kg/m3): 1830

Kuphwanya kukana (kg / m2): Kupanga kwa Chemical [SiO2]: ≥99.5

Kukula kowonjezera kwamafuta (x10-6): Moyo: Nthawi zoponya 200 kapena kupitilira apo kapena kupitilira chaka chimodzi

1. High geometric processing kulondola, zosavuta kukhazikitsa.

2. Mphamvu zazikulu, moyo wautali wautumiki, mtengo wotsika wokonza.

3. Zinthu zofananira komanso kutchinjiriza kwabwino kwamafuta.

4. Aluminiyamu yopanda ndodo, palibe kuipitsidwa kwa aluminiyumu kusungunuka.

5. Scour resistance, corrosion resistance of aluminium liquid Application Imagwiritsidwa ntchito patebulo loponyera aluminium billet, aluminiyumu yosungunuka imatsanuliridwa mu crystallizer ya nkhungu kuchokera ku Distribution launder pakuponya.Ikhoza kukwaniritsa zofunikira zaumisiri za kuponyedwa kolondola kwa aluminiyumu aloyi.

Kukula konse kumatha kusinthidwa, kupereka zojambula kapena zitsanzo musanagule.